SERVICES

Home » Services

OUR ADDED VALUE.

Not just products: Montenero guarantees a top offer also with regard to the range of exclusive services made available to its customers.

Whether it is the design of tools tailored to meet the specific needs of the customer, the balancing and testing of the product before implementation or the scheduled or extraordinary maintenance of the tool, everything contributes to creating a product-service system, in the a sign of the professionalism of Montenero collaborators, where customer satisfaction is always at the center.

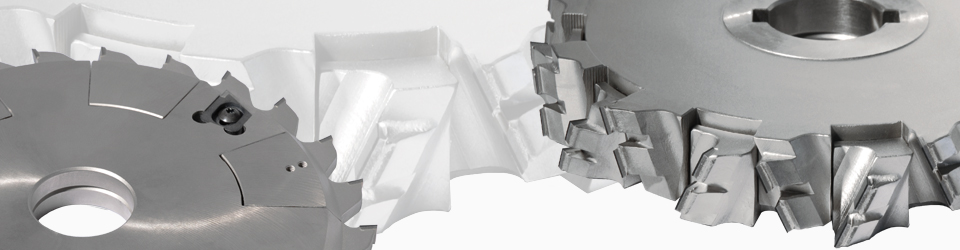

CUSTOM DESIGN

Not just products: Montenero guarantees a top offer also with regard to the range of exclusive services made available to its customers.

Whether it is the design of tools tailored to meet the specific needs of the customer, the balancing and testing of the product before implementation or the scheduled or extraordinary maintenance of the tool, everything contributes to creating a product-service system, in the a sign of the professionalism of Montenero collaborators, where customer satisfaction is always at the center.

Not just products: Montenero guarantees a top offer also with regard to the range of exclusive services made available to its customers.

Whether it is the design of tools tailored to meet the specific needs of the customer, the balancing and testing of the product before implementation or the scheduled or extraordinary maintenance of the tool, everything contributes to creating a product-service system, in the a sign of the professionalism of Montenero collaborators, where customer satisfaction is always at the center.

BALANCING - TESTING AND MARKING OF TOOLS

BALANCING - TESTING AND MARKING OF TOOLS

Not just products: Montenero guarantees a top offer also with regard to the range of exclusive services made available to its customers.

Whether it is the design of tools tailored to meet the specific needs of the customer, the balancing and testing of the product before implementation or the scheduled or extraordinary maintenance of the tool, everything contributes to creating a product-service system, in the a sign of the professionalism of Montenero collaborators, where customer satisfaction is always at the center.

SHARPENING

Not just products: Montenero guarantees a top offer also with regard to the range of exclusive services made available to its customers.

Whether it is the design of tools tailored to meet the specific needs of the customer, the balancing and testing of the product before implementation or the scheduled or extraordinary maintenance of the tool, everything contributes to creating a product-service system, in the a sign of the professionalism of Montenero collaborators, where customer satisfaction is always at the center.